ARG - Automated Robot Guidance - is a vision system designed specifically to ensure the tightening and drilling operations on the Stop & Go production lines. An easy-to-use system which sets a new standard for tightening and drilling precision in robotic guidance by ensuring alignment recovery of end of arm tooling.

By addressing the challenge of repeatability and positioning of parts on production lines.

Using 3D vision to find tightening/drilling points and auto-align with holes or bolts

Eliminates the need for costly, complex, and inflexible mechanisms

Thanks to a tool that is easy to set up, use and maintain.

ARG - Automated robot guidance in video

An integrated solution by Desoutter

An all-in-one kit made up of 4 components

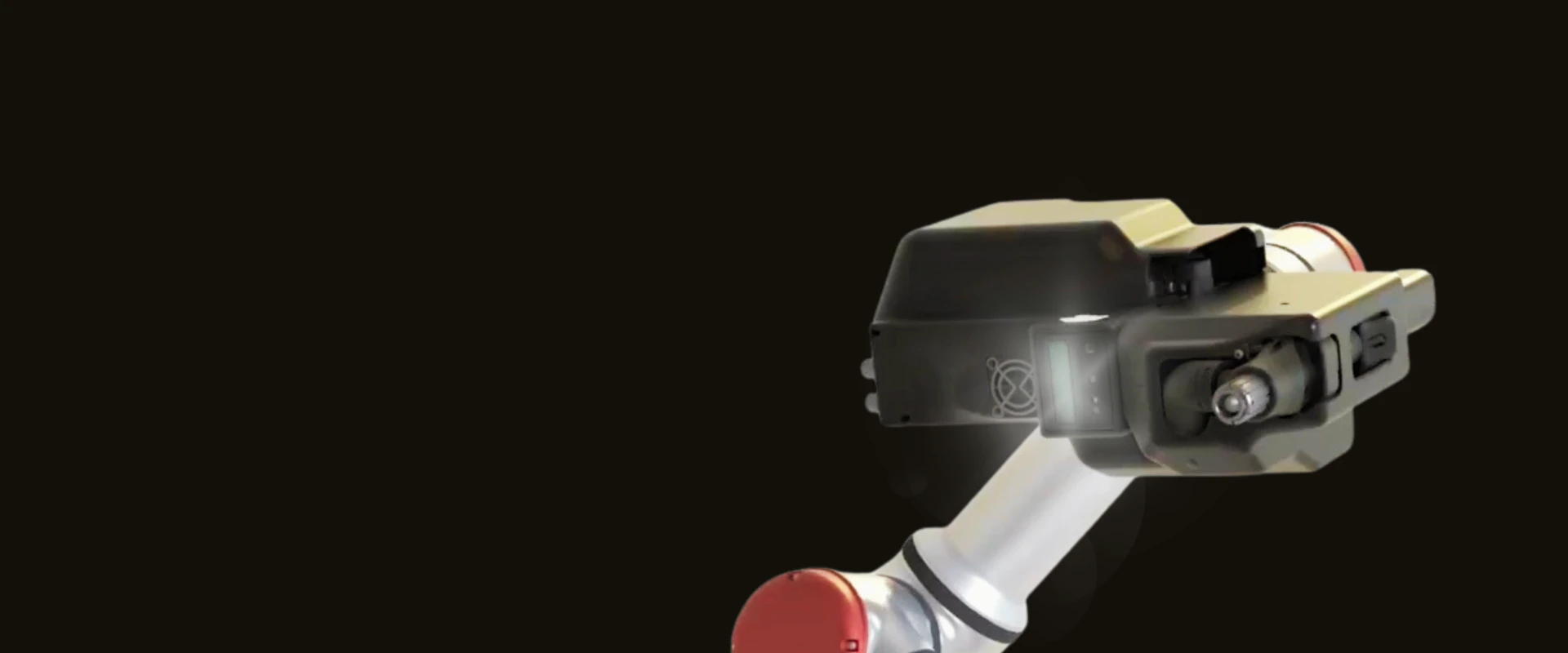

The camera

The small camera can capture 3D clear pictures close to the application for process optimization.

The processor

The GPU-based computer runs the ARG software that uses IA models to analyse the 3D pictures.

The lighting device

A series device with every model in case of very low light exposure of the assembly.

The software

An HMI gives customers full ownership for a large majority of applications. Some complex applications can require the use of the low-code software, also provided.

The camera

The small camera can capture 3D clear pictures close to the application for process optimization.

The lighting device

A series device with every model in case of very low light exposure of the assembly.

The processor

The GPU-based computer runs the ARG software that uses IA models to analyse the 3D pictures.

The software

An HMI gives customers full ownership for a large majority of applications. Some complex applications can require the use of the low-code software, also provided.

Made for non-repeatable tightening and drilling points location

Global assembly positioning

The vehicle or the conveyor moving the assembly from one station to the other performs stops in inaccurate positions.

Key facts

3D vision

A high-precision depth detection

Fast batch detection

Tens of holes detected in one picture acquisition

Less than 1 second

Time to process and send tightening and drilling points coordinates

Supported robots

All industrial robots and cobots

A smaller device for a greater vision

- Extra-compact and light camera directly installed on the tool.

- Performance ensured thanks to the GPU and the AI-based analysis software.

- Ability to detect different features such as holes or pre-mounted screws.

A 3D vision adapted to the industry's needs

- A non conventional camera, by its compactness and precision.

- Use of the VCSEL technology for high-precision depth detection.

Let's talk

Would you like to study how to integrate ARG into your assembly line?

A device made for performance

- Batch detection: a single picture acquisition to detect a mix of holes and bolt heads in a region of interest.

- Razor-sharp precision with 100% detections within positioning tolerances.

An innovative AI-based tool

- Artificial Intelligence models providing highly accurate analysis of pictures adapted to all types of use cases.

- A scalable system which allows an easy change of part design and duplications with pre-learned AI models tailored to the specific use cases.

Reduce programming time

- A scalable tool that operators can configure on any Stop & Go production lines.

- Easy to install, configure and maintain, for total customer ownership.

Other questions about Automated robot guidance

How does vision improve robot performance?

Vision enhances robot performance by providing accurate spatial data, allowing for precise positioning of end of arm tooling. It increases adaptability by allowing cobots to handle a variety of tasks without reprogramming.

What are the primary applications of vision with robots?

Primary applications include assembly line automation, where vision guides robots in placing and fastening components; quality inspection, where it detects defects and ensures product conformity; and material handling, where it aids in picking and placing items with high accuracy.

What are the benefits of using vision systems in collaborative robots?

Benefits include enhanced precision in tasks such as assembly and inspection, improved safety through real-time environment monitoring, and increased flexibility in handling diverse and complex tasks. Vision systems also enable cobots to work more effectively alongside human operators.

How do you integrate vision systems with robots?

Integration involves mounting a camera on the robot, calibrating the vision system to the robot's coordinate system, and programming the robot to interpret and act on the visual data. This process may require specialised software and expertise in both robotics and computer vision.

What factors should be considered when choosing a vision system for robots?

Considerations include the accuracy and speed of the vision system, compatibility with existing robotic hardware and software, the complexity of the tasks to be performed, and the system's ability to operate in various lighting conditions. Cost and ease of integration are also important factors.

What is 3D vision in robotics?

3D vision in robotics involves using stereoscopic cameras or structured light to capture depth information, enabling robots to perceive and interact with their environment in three dimensions. This technology is essential for tasks requiring high precision and spatial awareness.